Isotherm Safety Glass

Our production and services

Safety Glass

Tempered glass is a float or ornamental glass that is resistant to temperature changes, to impact and also has greater bending strength.

For this reason, it can also be used as a structural element. When it is broken, the whole pane shatters into cubes which, for the most part, do not have sharp edges and are not connected to each other.

Thanks to this property, various injuries are prevented to a large extent. These properties are based on the internal transverse tension of the glass when it is hardened (tempered).

Tempered Glass ESG

ESG – Single Thermally Tempered Safety Glass

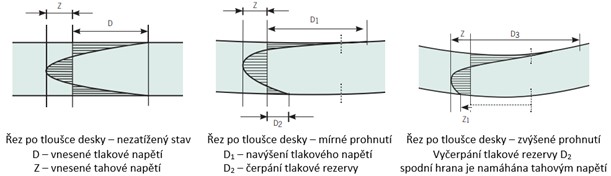

It is a glass in which a permanent surface pressure stress (pressure reserve) is induced by a specially controlled heating and cooling process in order to significantly increase the resistance to mechanical and thermal stresses.

Due to the imposed stress, a large number of small fragments are formed when the glass breaks. The data concerning thermally toughened glass are given in standard ČSN EN 12150.

It is used in cases of higher tensile stresses (e.g. temperature changes, resistance to side impact i.e. impact on the glass surface) and for safety purposes. In terms of protection against injury, they are used as fillings for shower enclosures, glass doors or other interior accessories where safety measures are required.

Fracture characteristic

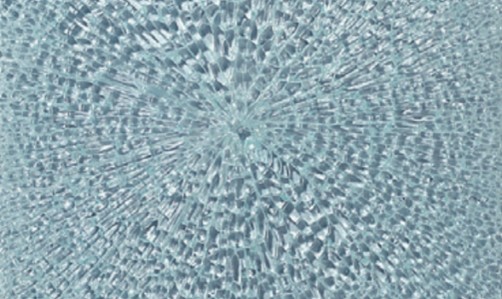

When tempered safety glass breaks, it breaks into small fragments due to internal pre-stressing (a measure of accumulated energy). This maximises the level of safety.

The quality of the hardening is evaluated by the number of fragments in a 50 mm square. The maximum length of the longest fragment shall not exceed 100 mm. The minimum number of fragments for each type of glass is specified in ČSN EN 12150 – 1.

Fracture structure of thermally toughened safety glass.

TVG – Simple heat-strengthened glass

As with thermally toughened glass, this is also the case with heat-treated glass. However, the difference is that the cooling process is longer and therefore the resulting internal stress is lower.

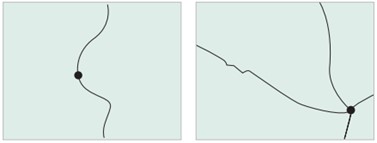

The principle of the resulting prestress is the same in both cases (ESG, TVG). In connection with the longer cooling process, the nature of the shards of broken heat-strengthened glass is identical to that of conventional float glass (see ČSN EN 1863).

They are most commonly used in combination with safety film in cases of laminated safety glass applications such as overhead glazing or cantilever glazing (e.g. railings). Due to their shatterproof nature, they provide the necessary residual load-bearing capacity in the event of glass breakage.

Heat strengthened glass crack propagation – always on the edge of the board

Laminated Glass VSG

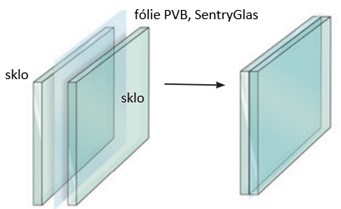

Layered glass units (VSG) consist of two or more sheets of glass that are bonded together by one or more flexible and strength-resistant film layers (mainly PVB, EVA, SentryGlass).

The safety capability is based on the high strength and toughness of the film, its adhesion to the glass and the residual load capacity of the broken glass. If the laminated glass meets safety class 3(B)3 (according to EN 12600), it is laminated safety glass (ČSN EN 14449, ČSN EN ISO 12543).

The number of panes of glass and intermediate layers determines the level of protection. It is always important to evaluate the laminate application with regard to residual load capacity after breakage.

In the event of breakage, the shards are firmly attached to the film that holds the glass together. These glasses are used in case of higher security requirements (injuries or collapses, statically demanding constructions) or as protection against manual attacks or natural elements (e.g. vandalism, shooting, extreme weather conditions). Glass provides both active and passive safety. Passive safety is the protection of a person from injury caused by the glass itself.

Advantages of laminated safety glass

- protection of persons (from injury to health or life) and objects (from damage or theft)

- implementation of load-bearing glass structures

- residual load capacity in case of breakage of the laminate (depending on the type of glass and the interlayer used)

- increase in soundproofing

- reduction of UV transmission (PVB) – use in fire-resistant glass

- increased UV transmittance (SentryGlas)

- reflection of thermal energy

- by combining glass with different types of foils, any requirement can be met (design and physical-mechanical requirements)

Maximum glass dimensions

Max. float glass size according to EN 12150-1

4.0 mm and more 1500 × 2500 mm

4.7 mm and more 2000 × 3000 mm

6.0 mm and more 2440 × 4800 mm

Max. size of soft coated glass according to EN 12150-1

4.0 mm and more 1400 × 2400 mm

4.7 mm and more 1500 × 2500 mm

6.0 mm and more 2000 × 3000 mm

Glass above the maximum and below the minimum dimension or above the maximum weight – by agreement with the manufacturer.

Fire Resistant Glass

Fire-resistant glazing. Fire protection is the ability of a structure to resist the effects of combustion. It is expressed by the length of time a building structure is exposed to fire without impairing its function.

The primary purpose of fire-rated glass is to retain the visual characteristics of ordinary clear glass in standard use and, in the event of a fire, to provide protection for the required and guaranteed period of time.

Glass, like any other fire protection structure, always resists a fire for a certain period of time, which is the main parameter to be monitored. In general, the aim of fire protection structures is to enable the occupants to escape safely from the area of the fire and to effectively prevent its further spread.

Characteristics of materials with fire resistance

- load capacity / stability – R

- integrity – E

- temperatures on the unheated side (insulation) – I

- heat flux density (radiation) (vyzařování – radiace) – W

- smoke resistance- S

- mechanical action – M

- self-closing mechanism – C

- fire protection efficiency – K

The fire resistance classification is expressed by the above designation and by the time t in minutes for which the structure under consideration meets the characteristic properties. Combinations of individual characteristics may be used in the designation of the structure.

Today, there are different types of fire-resistant glass based on different manufacturing methods. In addition to basic protection against the penetration of smoke or fire itself, fire glass now offers protection against heat penetration and also ensures the psychological well-being of people by making the glass opaque (at a given higher temperature, the interlayer is softened).

The classification of fire-resistant glass states the following basic classes E, EW, EI (E – preservation of integrity, W – reduction of radiation, I – insulation). With regard to the requirement of thermal insulation, the glass is marked with the symbols EI (temperature criterion) and EW (heat flux density criterion).

According to these criteria, fire-resistant glass can be divided into

- EW-class glass (fire-resistant, heat-reducing glass). Increased integrity – physical barrier against flames, smoke and fumes

- EI-class glass (fire-insulating glass that limits heat transfer). Full thermal insulation – thermal and physical barrier against fire, based on specific surface temperature limits in standard condition tests. Protection against all types of heat conduction i.e. conduction, radiation, convection.

Depending on the type of the final product and the concept of its functioning, fire-resistant glass can be further divided into

- polished wire glass

- tempered borosilicate glass

- special heat-strengthened glass

- coated tempered monolithic or insulating glass

- laminated glass with gel

- laminated glass with a thermally reactive expanding layer

Fire-resistant glass with thermally reactive coating.

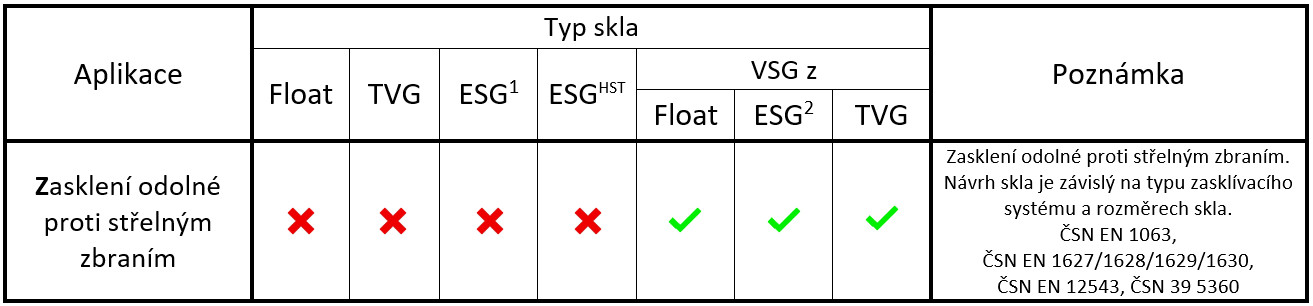

Bulletproof Glass

BR1 (puška, 3 zásahy), BR2 (pistole, 3), BR3 (revolver, 3), BR4 (revolver, 3), BR5 (puška, 3), BR6 (puška, 3), BR7 (puška, 3) a brokové zbraně SG1 (brokovnice, 1) a SG2 (brokovnice, 3). Třídy BR1 – BR7 jsou seřazeny podle úrovně poskytované ochrany (tzn. sklo, které odpovídá požadavkům stanoveným pro danou třídu, rovněž splňuje požadavky nižších tříd). Úroveň ochrany u tříd BR a SG nelze porovnávat, protože je použito rozdílné střelivo.

Financial institutions, military installations, money changers, etc. ČSN EN 1063 specifies performance requirements and test methodology for the classification of firearms resistant glass (consisting of one or more layers of glass) and glass/plastic combinations.

The protection provided by bulletproof glazing is not only dependent on the product itself, but also on the fixing of the glass. The attachment rails and frames must meet the same level of protection as the glass that is categorised in the weapon being tested according to the following requirements:

- the glazing is not penetrated by a projectile or part of a projectile and the film is not penetrated by glass fragments from the rear side (relevant class + NS marking)

- the glazing is not penetrated by a projectile or part of a projectile but the film is penetrated by glass fragments from the protected side (relevant class + S marking)

According to EN 1063, bullet-resistant glass is classified into 9 classes. The standard distinguishes resistance to two types of firearms – pistols, rifles (BR class) and shotguns (SG class). In each category of firearm tested, the glass is classified as bullet resistant if no bullet or part of a bullet has penetrated it. The resulting report also determines whether or not (S) glass fragments were generated (NS) from the back side.

Notice:

A practical test must be carried out for each case, as the values given correspond to the standard samples and the test environment.

Bulletproof glass guarantees safety against firearms only. Protective glazing used as a sight glass, for example in rotating parts test rooms, cannot be assessed on the basis of EN 1063.

+43 7239 20 478

Sales department

office@isotherm-glas.at

ISOTHERM Glas GmbH

Gewerbepark 6

4201 Gramastetten

GPS: 96C7+MH Gramastetten, Austria